Cost Factors to Consider When Buying a Paper Slitting Machine

Investing in a paper slitting machine is a significant decision for companies in the paper, printing, and packaging industries. While performance and efficiency are critical, understanding the cost factors is equally important to ensure long-term value. Below are the main cost considerations when purchasing a paper slitting machine.

1. Initial Purchase Price

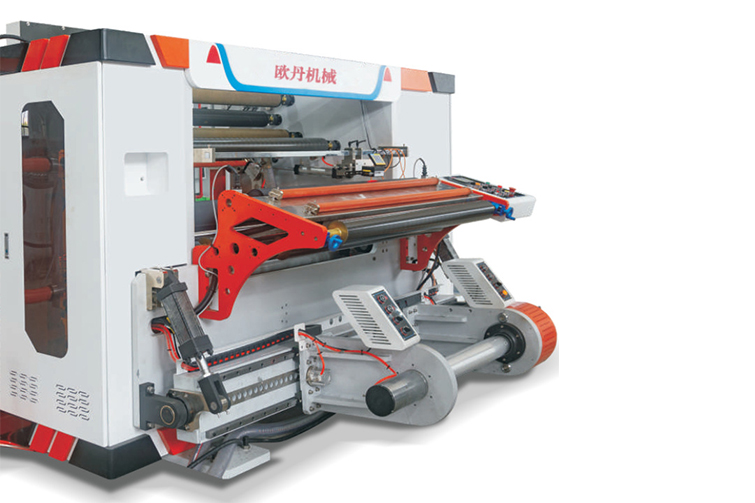

The upfront cost depends on the machine’s type, size, and level of automation.

- Basic models (manual or semi-automatic) are more affordable.

- High-speed, fully automatic models with advanced controls are more expensive but increase efficiency and reduce labor costs.

Tip: Consider long-term productivity rather than just the lowest purchase price.

2. Production Capacity and Efficiency

Higher capacity machines cost more but may lower per-unit processing costs.

- Speed: Faster machines handle larger volumes, saving time.

- Precision: Reduces waste, which indirectly lowers material costs.

3. Material Compatibility

The cost varies depending on the machine’s ability to handle different materials:

- Thin paper, thick cardboard, films, or laminated materials require different blade systems.

- Specialized machines for coated or high-value papers are usually more expensive.

4. Automation and Technology Features

Advanced technology often means higher upfront costs but greater long-term savings.

- Automatic tension control

- Edge alignment systems

- Digital display panels

- Rewinding functions

These features improve accuracy, reduce manual labor, and minimize errors.

5. Energy Consumption

Operating costs include electricity usage.

- Energy-efficient models may cost more initially but reduce long-term expenses.

- Always compare the operational cost per hour when evaluating machines.

6. Maintenance and Spare Parts

Ongoing costs include blade replacement, routine servicing, and potential downtime.

- Choose machines with easy-to-replace parts.

- Check whether the manufacturer provides local service and spare parts support.

7. Training and Labor Costs

Some machines require skilled operators.

- Manual models: Lower purchase cost but higher labor demand.

- Automated models: Higher purchase cost but reduced labor needs and fewer errors.

8. After-Sales Service and Warranty

A strong after-sales service package adds value to your purchase.

- Extended warranties may cost extra but reduce risks.

- Technical support ensures minimal downtime and greater efficiency.

Conclusion

When buying a paper slitting machine, consider not only the initial purchase price but also the long-term costs of efficiency, energy use, maintenance, labor, and after-sales service. A well-chosen machine should balance performance and cost-effectiveness, delivering consistent value and supporting business growth.